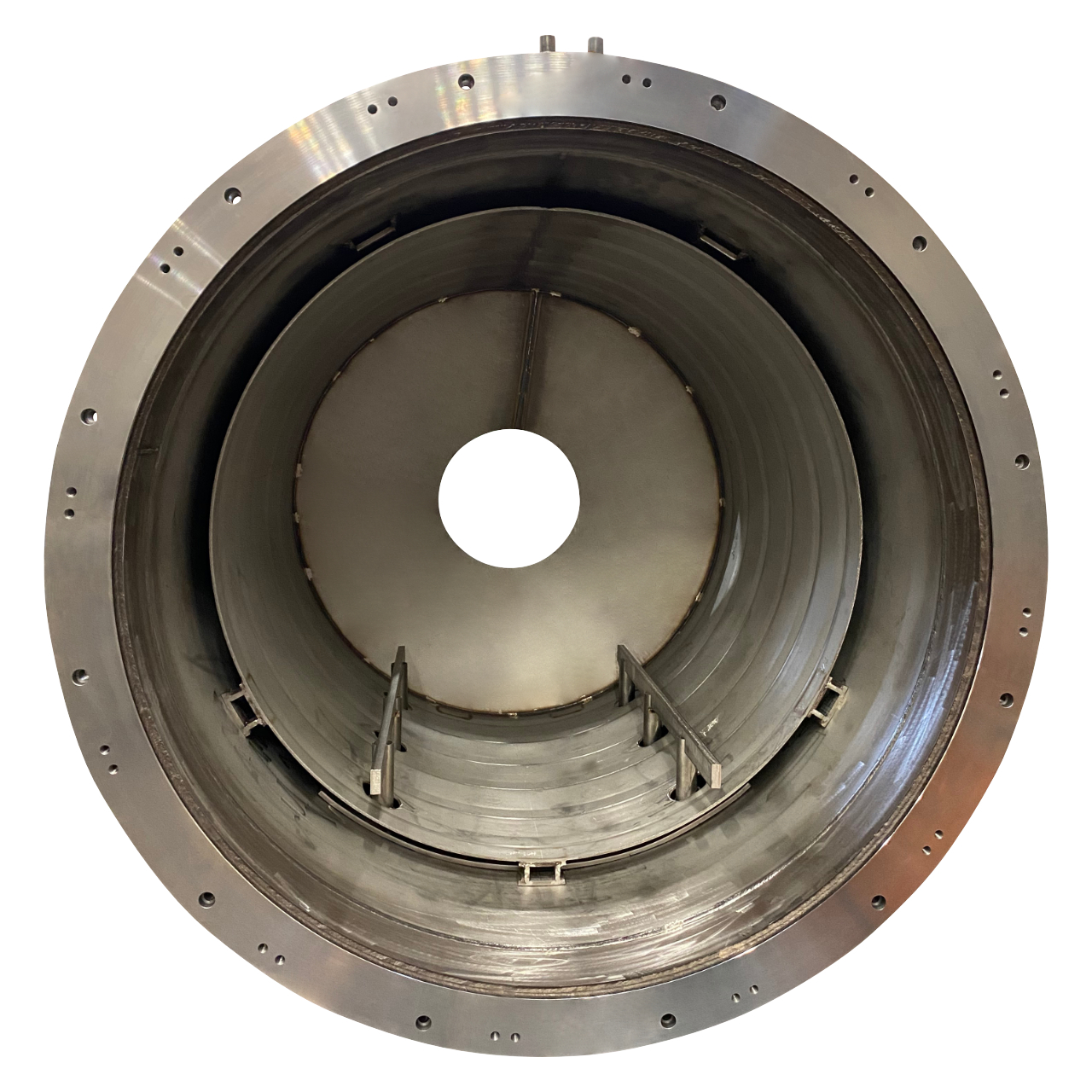

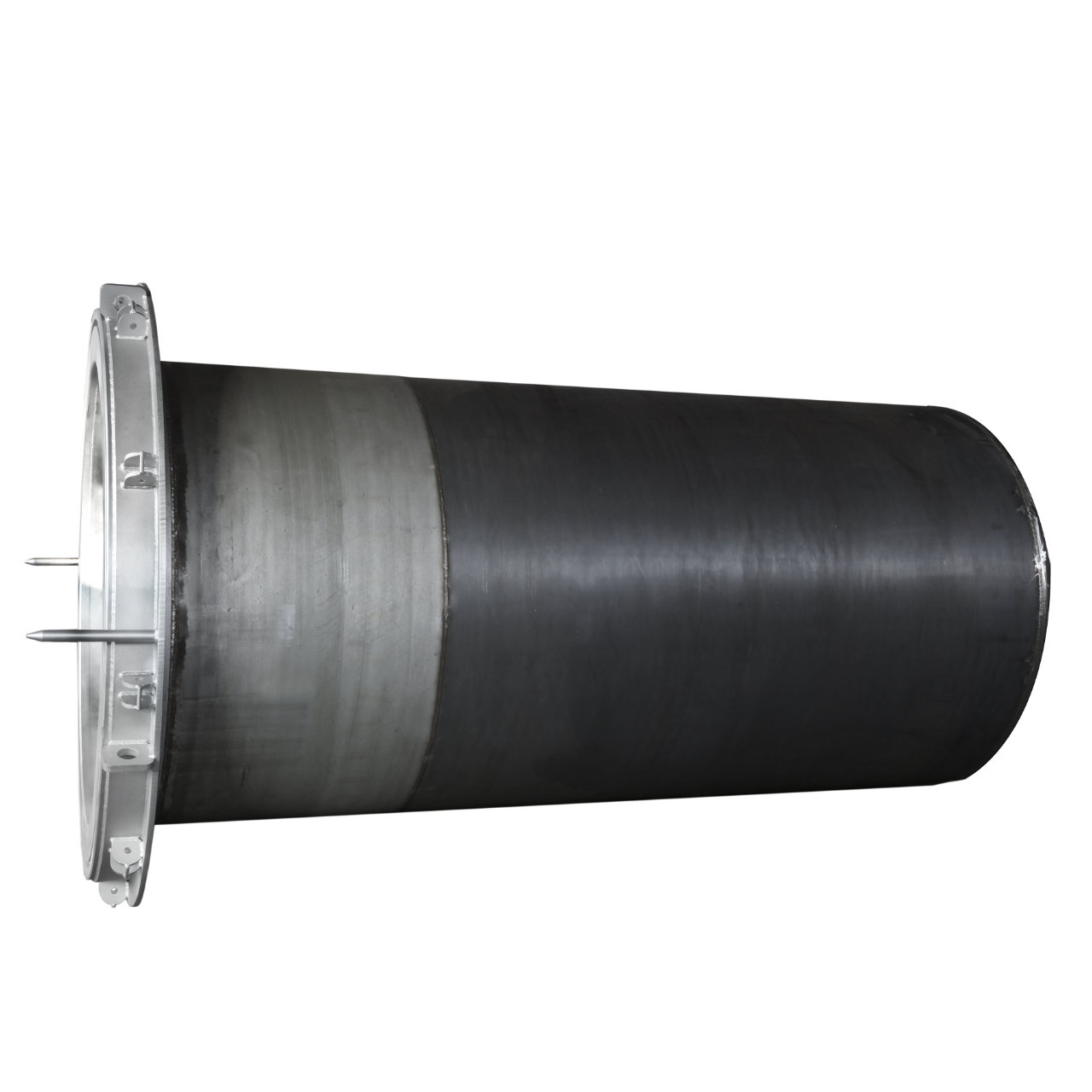

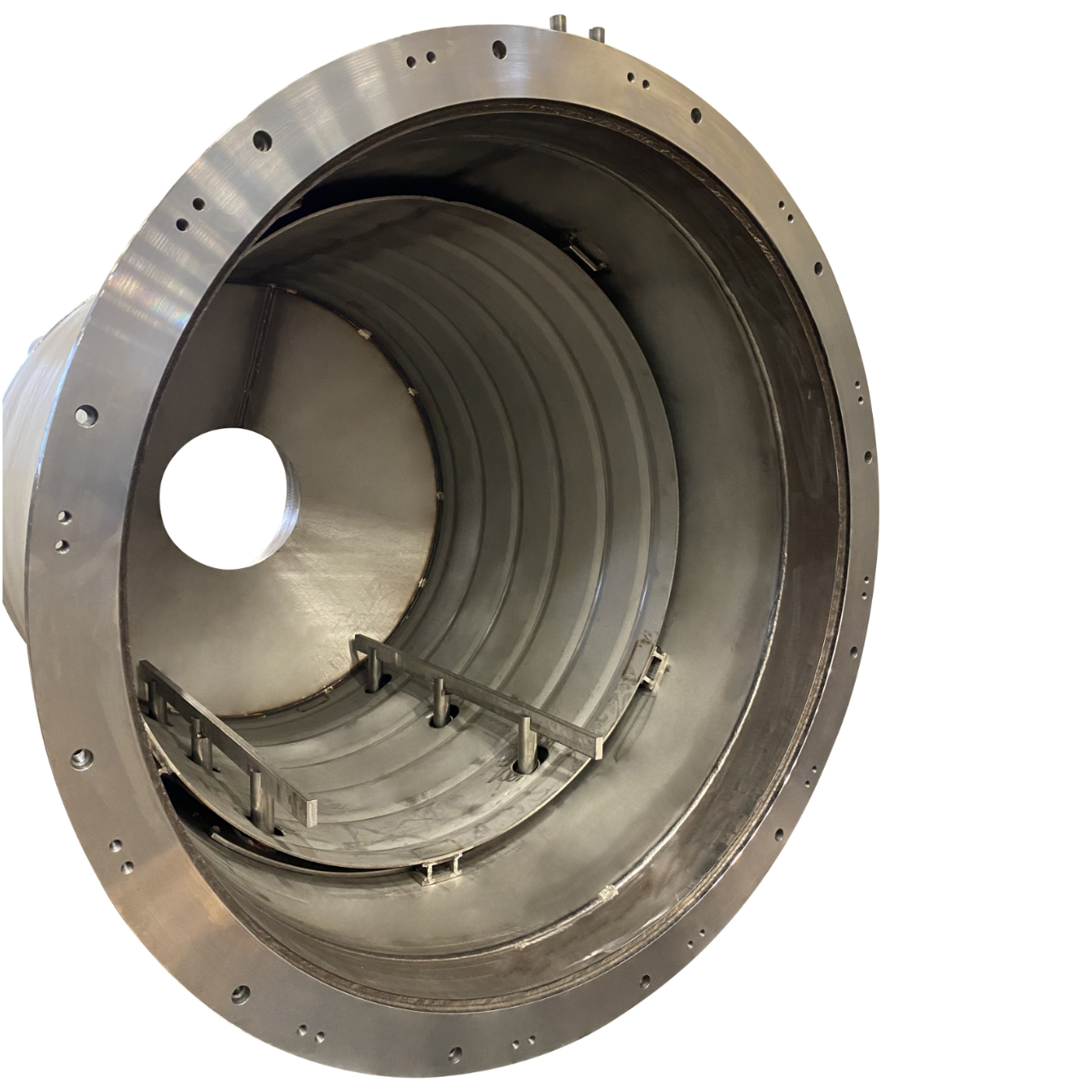

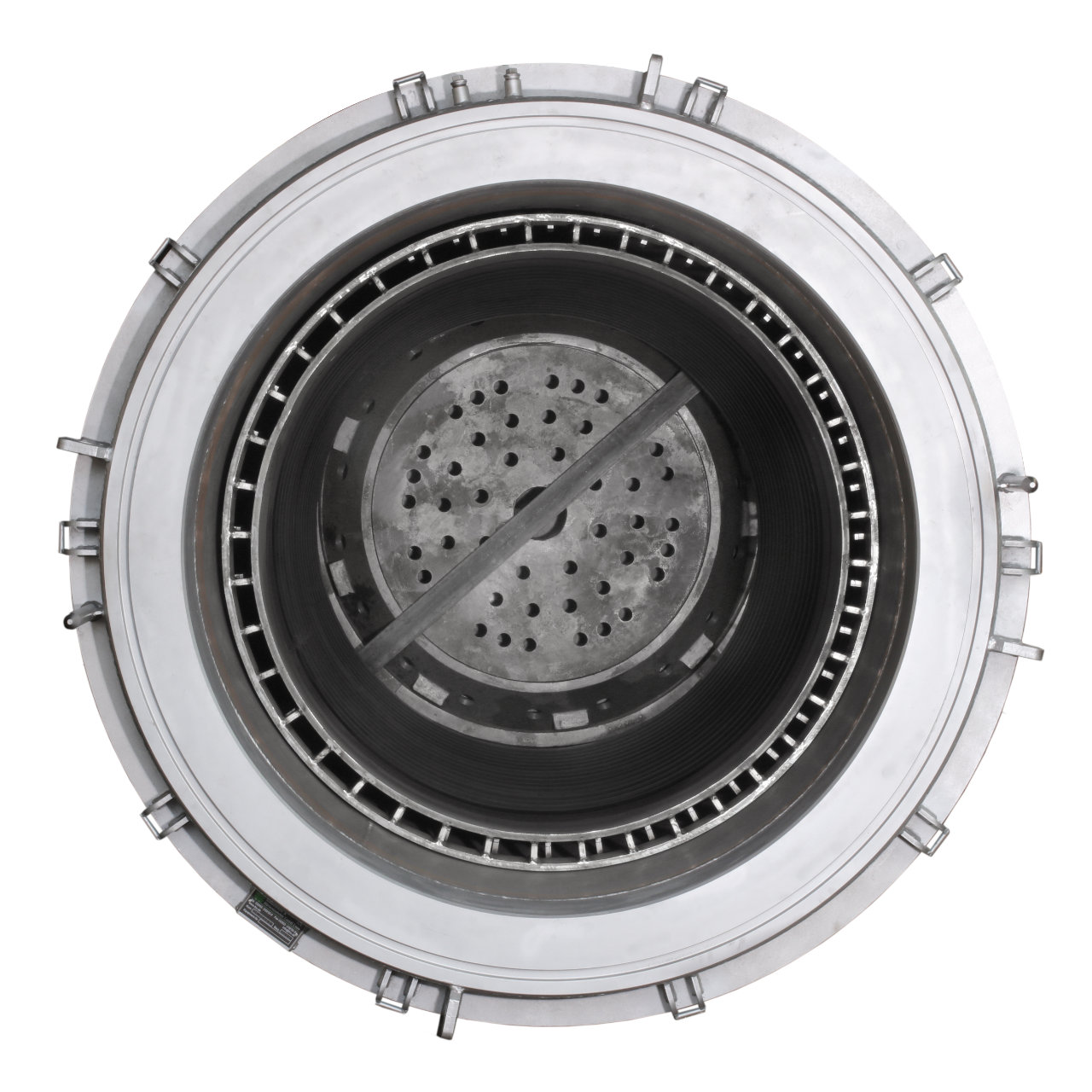

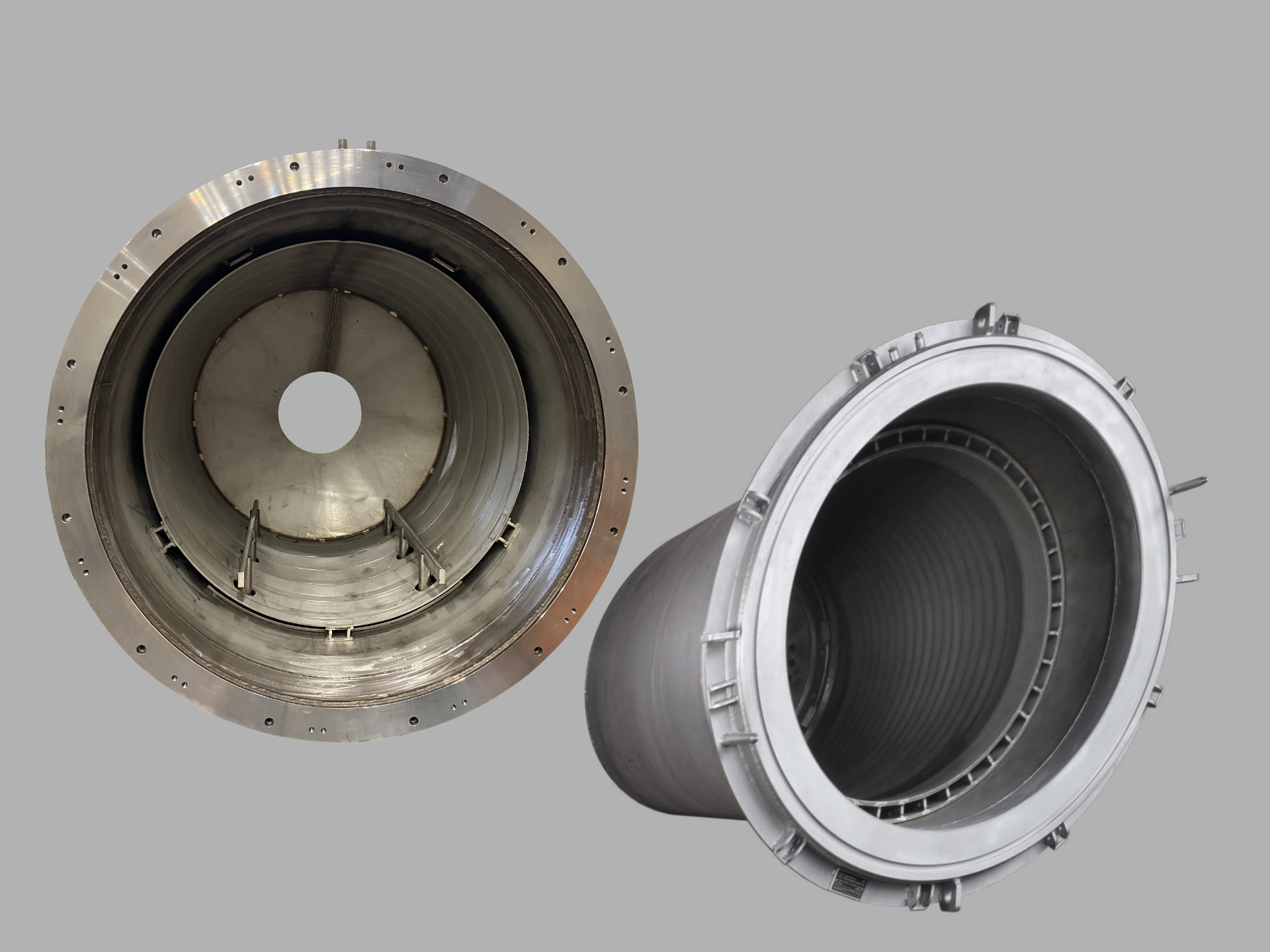

The currently strong orientation on maintenance works, overhauls and repairs to our customers’ existing furnace systems, sets the focus on the retort as the process room and centre of the furnace.

In the past few months, we have noticed a growing demand for furnace retorts, both for shaft furnaces and chamber furnaces, which we would like to take as an opportunity today, to provide you with a customer information.

Our own production at the company location in Unna is well prepared for this market situation with an experienced team, a well-equipped machine park and a selected, mostly regional supplier network.

Our retorts can be manufactured by us in Unna, up to a clear diameter of 4800mm, whereby we master the processing of many special materials.

Our machines offer a working width of 3000mm. This partly enables savings to be made on circular weld seams, which we exploit for the benefit of quality, whenever possible.

We are always available for quotations, technical advice and services and wish you and your team continued good health!