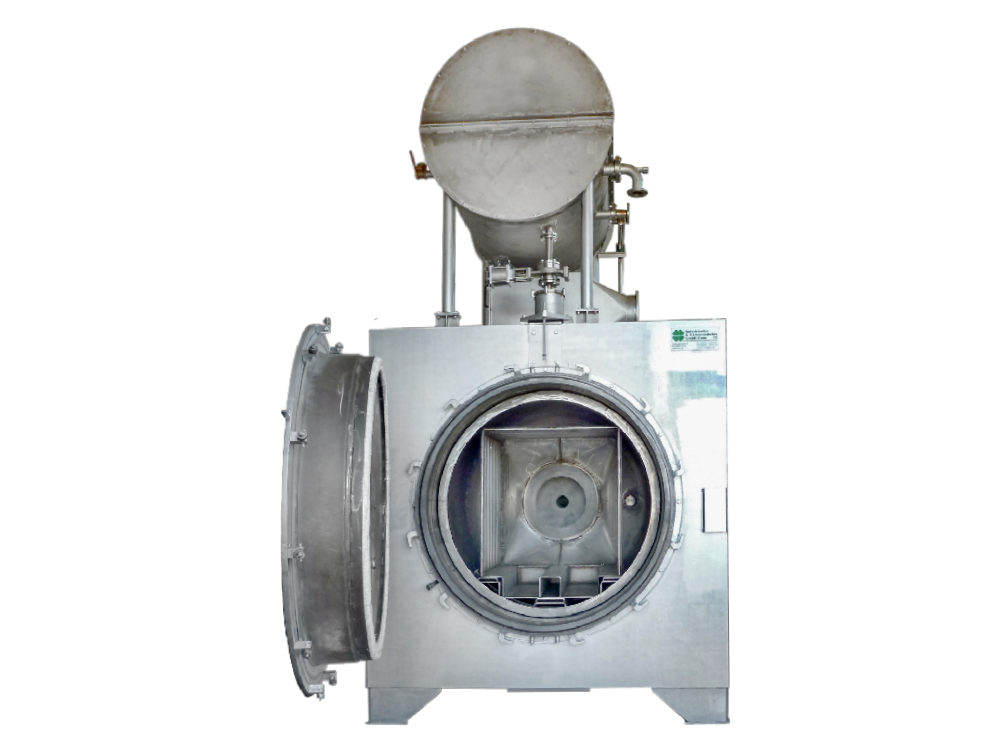

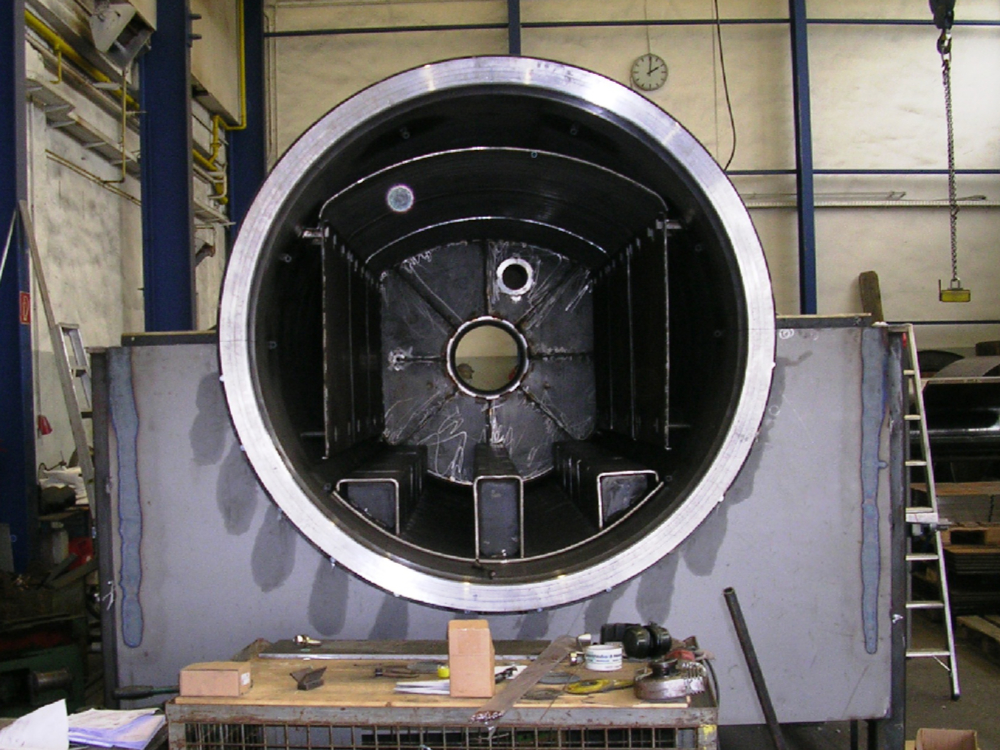

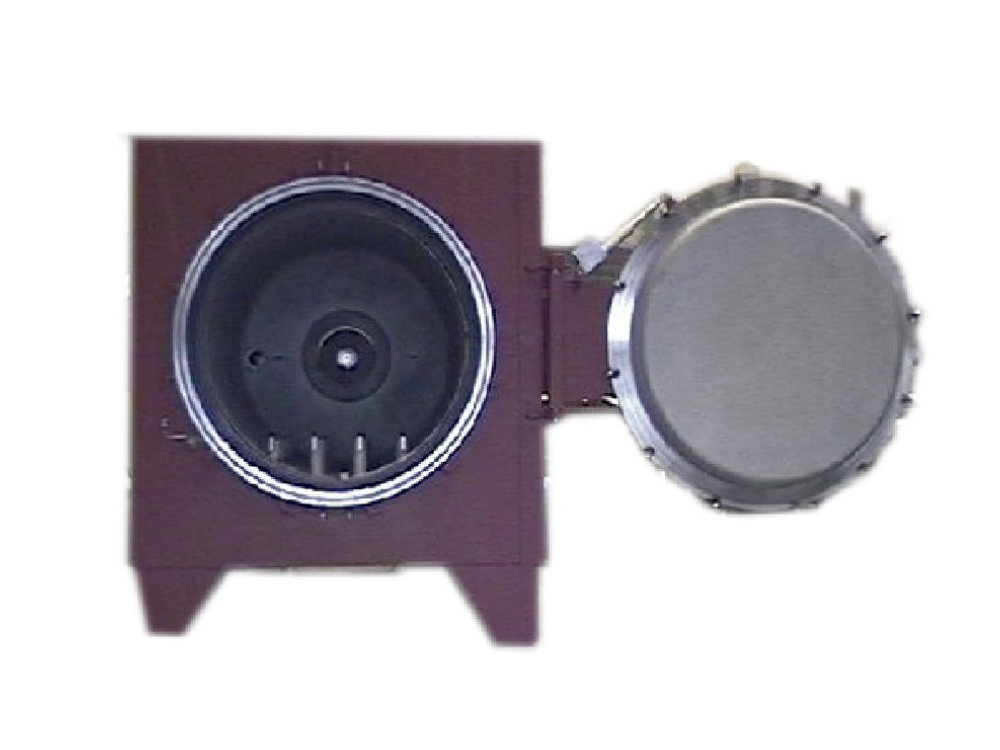

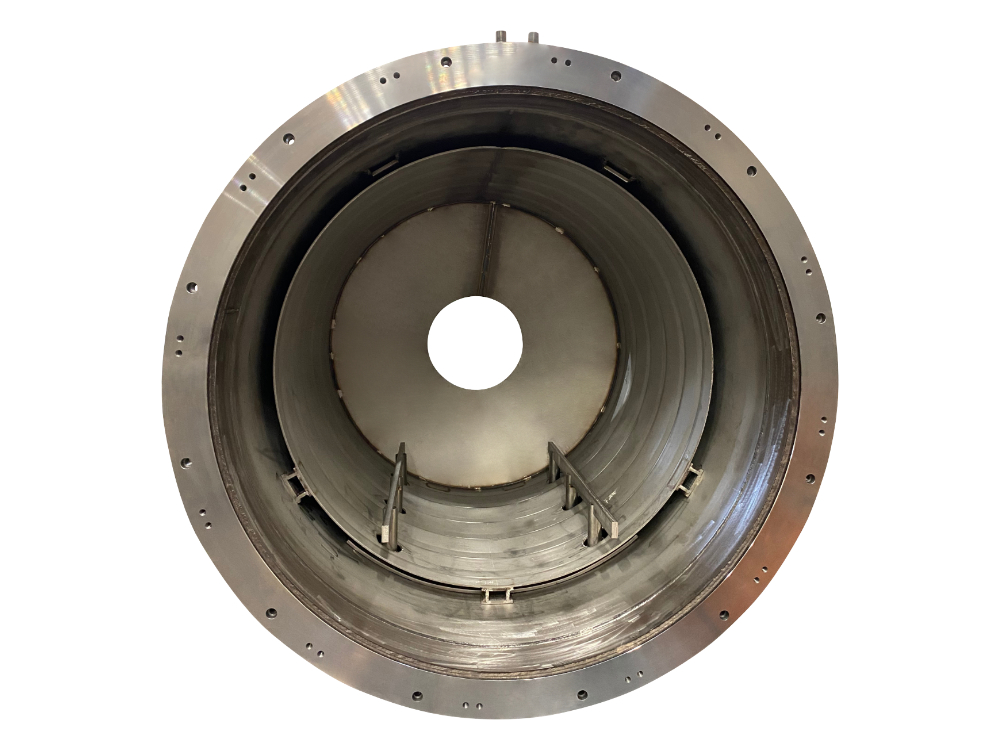

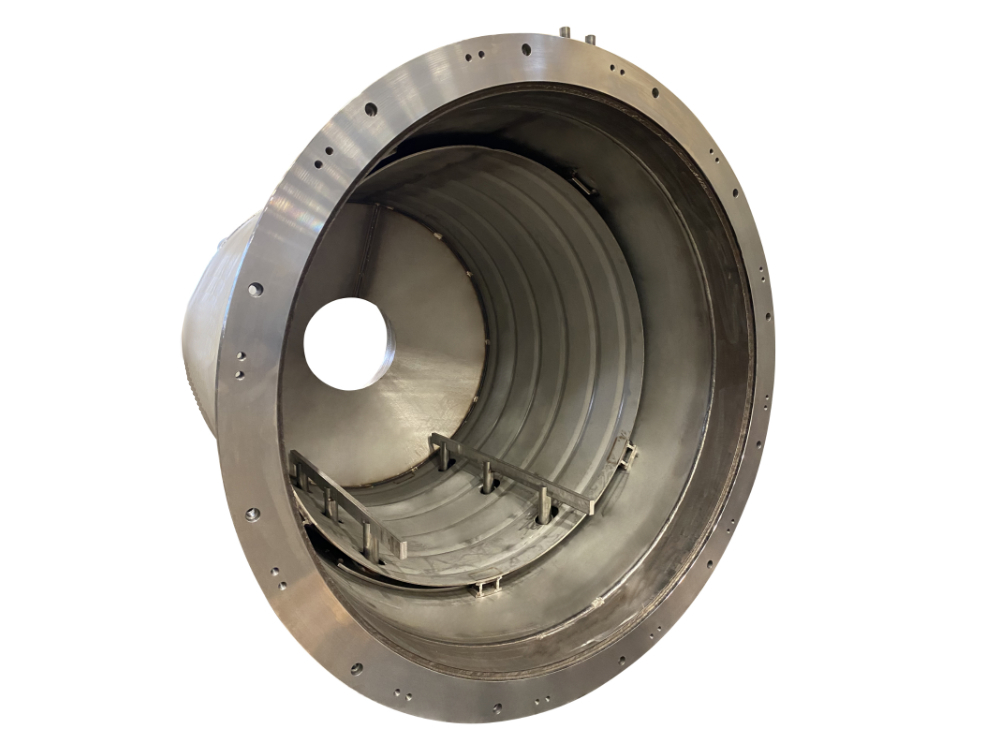

Our chamber furnaces for the horizontal charging are a stable profile iron construction. You can order your furnace with or without a horizontally installed retort (including charge support). Thanks to a special suspension, the retort is largely relieved of the charge weight.

Please find details concerning our components at our accessories.

Max. usable dimensions: Previously 1600 x 1600 x 3200mm

Max. charge weight: Previously 6.000kg

According to the customer requirements, other dimensions can be realized on agreement.

At the front, the chamber furnace is equipped with a fixed pivoting device for the manual opening and closing of the front retort door. The door is locked (bayonet fixing) by an electrically driven servomotor.

Depending on your needs and the desired cooling time, we can integrate a fast cooling device for the furnace chamber and/or a side stream fast cooling device for the cooling of the charge under forming gas atmosphere.

Our chamber furnaces are completely lined with low memory lightweight insulation and can be operated until a maximum temperature of 1000°C.

We offer you many possibilities for the execution of your furnace in electric or gas heated construction and are happy to advise you regarding this issue.

In case of a gas heated furnace, we deliver you the complete heating system, from the gas burner, to the gas train, until the gas station. Moreover we offer you the exhaust pipe as well as all the safety relevant equipment.

In the field of isolation, we work with many high-quality materials to avoid thermal bridges and to guarantee process safety as well as energy savings.

We gladly deliver you a media dosing unit for the supply and dosing of all the media relevant for the process.

We supply the complete installation technology with our partners as experts of this subject. Optionally, you can supervise, control and regulate your furnace by a modern PLC with touch-panel, which records temperature curves, transfers process information to the control centre and continuously executes a target-performance comparison of your process information.

We offer you quench baths for your components as well as washing machines for the subsequent cleaning.

DO YOU HAVE ANY QUESTIONS OR ARE YOU LOOKING FOR A CONTACT PERSON?

WE ARE HERE FOR YOU.

Get in contact